Plastic injection mould design

A Comprehensive Guide to Plastic

Injection Mould Design

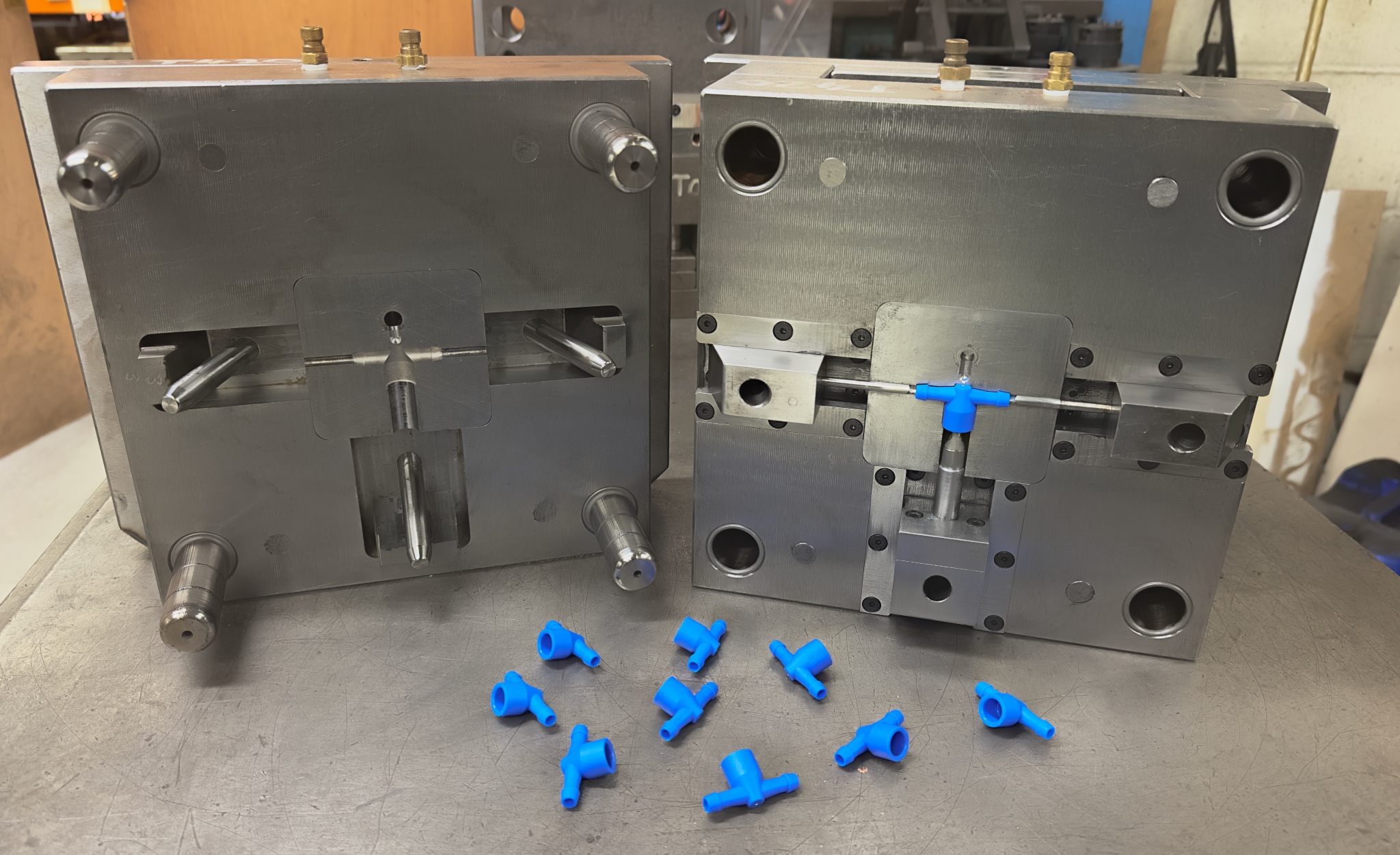

Plastic injection moulding is one of the most widely used manufacturing

processes for producing plastic parts with high precision and efficiency. The

process involves injecting molten plastic into a mould, where it cools and

solidifies to form the desired shape. While the injection moulding process is

relatively simple, the design of the plastic injection mould itself plays a

critical role in the overall quality, cost, and speed of production. In this

blog post, we will explore the key elements of plastic injection mould design,

including specifications and best practices for achieving optimal results.

What is Plastic Injection Mould

Design?

Plastic injection mould design refers to the process of designing a mould

that will be used in the plastic injection moulding process to produce plastic

parts. The mould is essentially a hollowed-out shape into which molten plastic

is injected under high pressure. Once the plastic cools and solidifies, the

part can be ejected from the mould.

The design of the mould is critical to the success of the injection moulding

process, as it directly impacts the quality of the final product. A

well-designed mould ensures consistent production of high-quality parts,

reduces cycle times, minimizes material waste, and ensures the longevity of the

mould.

Key Stages of Plastic Injection Mould

Design

The design of a plastic injection mould involves several stages, each

requiring careful consideration of various factors, such as part geometry,

material properties, and mould material selection. Below are the main stages

involved in the design process:

1. Part Design and Material Selection

Before designing the mould, it is essential to have a clear understanding

of the part that will be produced. The part's geometry, dimensions, and

functionality will influence the mould design. Key factors to consider during

part design include:

- Wall thickness: Consistent

wall thickness ensures uniform flow of the molten plastic, reducing the

risk of defects like warping or sink marks.

- Undercuts: These are

areas of the part that are difficult to mould due to their shape. Special

mould features, such as lifters or slides, may be needed to release parts

with undercuts.

- Radii and

fillets: Sharp corners and edges should be avoided in part design, as they

can lead to stress concentrations and affect the part's strength.

Material selection is also critical. The type of plastic used influences

the design and performance of the mould. Common plastic materials include ABS,

polycarbonate, and polypropylene, each with its own properties and processing

requirements.

2. Mould Design and CAD Modeling

Once the part design and material are selected, the next step is the

actual mould design. This phase typically involves the use of Computer-Aided

Design (CAD) software to create a 3D model of the mould. The design must account

for various factors, including:

- Gate design: The gate is

the point through which the molten plastic enters the mould cavity. The

gate’s location, size, and type (e.g., edge, submarine, or pin gate)

influence the flow of material and the appearance of the part.

- Cooling system: An efficient

cooling system is essential for reducing cycle times and ensuring uniform

part quality. The design should include strategically placed cooling

channels that maintain a consistent temperature throughout the mould.

- Ejection system: The ejection

system is responsible for removing the part from the mould once it has

cooled. The design must include ejector pins or plates that apply uniform

force to ensure smooth ejection without damaging the part.

3. Mould Fabrication and Testing

After the mould design is finalized, it is time to fabricate the mould.

This involves precision machining of the mould cavities, cooling channels, and

other features based on the CAD model. Common fabrication methods include CNC

machining, electrical discharge machining (EDM), and wire EDM.

Once the mould is fabricated, it undergoes a series of test injections to

verify that it functions as intended. During these tests, the design may be

adjusted to address issues like incomplete filling, warping, or surface

defects. Multiple iterations of testing and refinement may be required to

ensure that the mould produces high-quality parts consistently.

4. Production and Optimization

Once the mould is tested and validated, it can be used for full-scale production.

During this phase, production parameters such as injection pressure,

temperature, and cycle time are optimized to ensure high-quality parts are

produced efficiently. Regular maintenance and monitoring of the mould are

necessary to prevent wear and tear, ensuring that the mould remains in good

condition throughout its lifespan.

Specifications to Consider in Plastic

Injection Mould Design

When designing a plastic injection mould, there are several important

specifications to consider to ensure that the mould performs efficiently and

produces high-quality parts:

1. Material Selection

The type of plastic used for the part determines many aspects of the

mould design, including the injection pressure, cooling rate, and material

flow. Factors such as the material’s melt temperature, shrinkage rate, and

viscosity must be considered to optimize the mould design.

2. Mould Durability

The mould must be designed for durability to withstand the stresses of

repeated injection cycles. Materials like hardened steel or beryllium-copper

alloys are commonly used for high-durability moulds, as they can resist wear

and maintain precision over time.

3. Part Design Features

The part design plays a major role in mould design. Features such as

thickness variations, ribs, bosses, holes, and threads need to be considered to

ensure that the part can be easily molded without defects. Proper venting and

gating are also necessary to avoid air traps and ensure smooth material flow.

4. Tolerances

Mould design must account for tight tolerances to ensure that parts meet

the required specifications. This includes considerations such as dimensional

accuracy, surface finish, and assembly fit.

FAQs About Plastic Injection Mould

Design

1. What is the importance of gate

design in injection moulding?

The gate design is critical because it controls the flow of molten

plastic into the mould cavity. A poorly designed gate can lead to defects such

as uneven filling, sink marks, or warping. Proper gate placement and size are

essential for high-quality parts.

2. How long does it take to design a

plastic injection mould?

The design process can take anywhere from a few weeks to several months,

depending on the complexity of the part and the mould. Detailed analysis and

testing are required to ensure that the mould performs efficiently and produces

parts with the desired quality.

3. Can injection moulds be used for

high-volume production?

Yes, plastic injection moulds are designed for high-volume production.

Once the mould is created, it can be used to produce thousands or even millions

of parts, making it ideal for mass production of plastic components.

4. What are the common challenges in

plastic injection mould design?

Some common challenges include managing complex part geometries, ensuring

proper cooling, preventing material defects, and optimizing cycle times. Mould

wear and tear can also impact the performance and longevity of the mould.

5. How can I improve the efficiency of

the injection moulding process?

Improving efficiency can be achieved through optimized mould design, such

as ensuring proper gate placement, enhancing cooling system design, and

reducing cycle time. Additionally, regular maintenance and careful material

selection can enhance process efficiency.

Conclusion

Plastic injection mould design is a complex and crucial process that requires careful attention to detail, from the part design to the final production run. A well-designed mould ensures high-quality plastic parts, efficient production, and reduced costs. By understanding the key specifications and stages of the design process, manufacturers can optimize their mould designs for maximum performance and reliability. Whether you're producing small components or large quantities, investing in the right mould design is essential for achieving long-term success in plastic injection moulding.