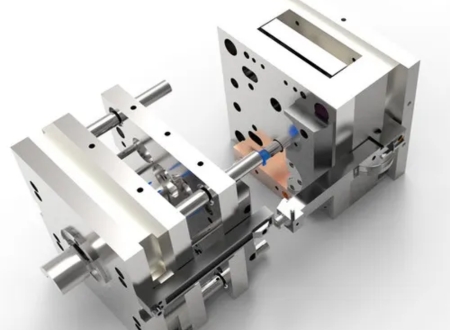

Plastic Injection Mould Design

Precision in Plastic Injection Mould Design: The Foundation of Quality Components

Plastic Injection Mould Design is the critical engineering phase that directly dictates the quality, cost-efficiency, and manufacturability of every plastic component produced. As an ISO 9001:2015 certified company, PLASMOTEK understands that a meticulously designed mould tool is the cornerstone of reliable and consistent manufacturing. Our design philosophy transcends simple geometry, integrating advanced principles of Design for Manufacturability (DFM) and mould flow analysis to ensure optimal part performance and production cycle times. We leverage our extensive experience since 1987 to focus on fundamental design elements such as uniform wall thickness to prevent warping and sink marks, the application of appropriate draft angles for seamless part ejection, and the strategic placement of gates and runners to ensure perfect material flow and minimal material waste.

Advanced Engineering for Custom Mould Development

The development of a high-performance custom plastic injection mould requires specialized technical expertise beyond standard CAD work; it involves sophisticated materials science and process simulation. Our R&D wing in Bangalore utilizes state-of-the-art software for complex Mould Development and Computer-Aided Engineering (CAE) simulations, including mould flow analysis, to predict and mitigate potential defects like knit lines, short shots, and dimensional inaccuracies before the first chip of tool steel is cut. This proactive approach to plastic mould design minimizes expensive and time-consuming rework, ensuring your final components meet precise specifications for tight tolerances. We specialize in various tooling types, including single-cavity, multi-cavity, and hot runner systems, selecting the most efficient and cost-effective solution tailored to your specific volume and complexity requirements.

Design for Manufacturability and Material Optimization

At PLASMOTEK, our team of experts integrates Design for Manufacturability (DFM) principles into every facet of the injection moulded components design process. This critical step involves a detailed review of your part geometry, ensuring features like ribs and bosses are correctly sized relative to the nominal wall thickness to maximize strength without causing surface defects. We also provide crucial guidance on material selection, navigating the properties of various commodity and engineering resins—from ABS and Polypropylene to high-performance polymers. The choice of plastic material profoundly impacts the mould's shrink rate, gate type, and cooling strategy, all of which are meticulously calculated during the initial design phase. By perfecting this intricate balance between part design, material properties, and mould engineering, we deliver superior, competitive, and reliable plastic moulded components with scheduled delivery periods.